|

WHAT ARE THE BENEFITS TO THE BAR?

BFS Prevents beer waste. The entire content of the keg is now available to sell. It saves a minimum of 3 to 4 pints per keg on an average draught beer run of 20 m'. The longer the run – the greater the savings. BFS prevents gas waste, particularly where mixed gas systems are in use and gas costs are high. BFS prevents foam from spraying in the bar. Bar tender saves time in tapping new kegs and pouring a perfect pint. WHAT ARE THE BENEFITS TO THE BREWERY?

Hygiene in the draft system is significantly improved, easier to maintain due to design and materials, stainless steel grade 316. Beer line is always full with beer from coupler to tap. No foam is trapped in the line. Sanitation – no need to dismantle the device and clean each component. The cleaning process is simple and fast. Simple installation attached directly to the keg coupler. |

HOW DOES IT WORK?

When a keg empties, the gas travels up the keg until it hits a small sensor located just 3 cm above the dispense coupler. This immediately blocks the line, beer stops pouring. As a new keg is tapped, and the coupler re-attached, switches the BFS to the ON position. A new perfect pint can be easily poured. |

Foam Stop manual

|

| ||||||||||||

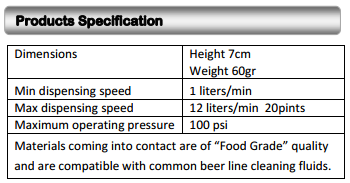

TECHNICAL data

|

| ||||||||||||