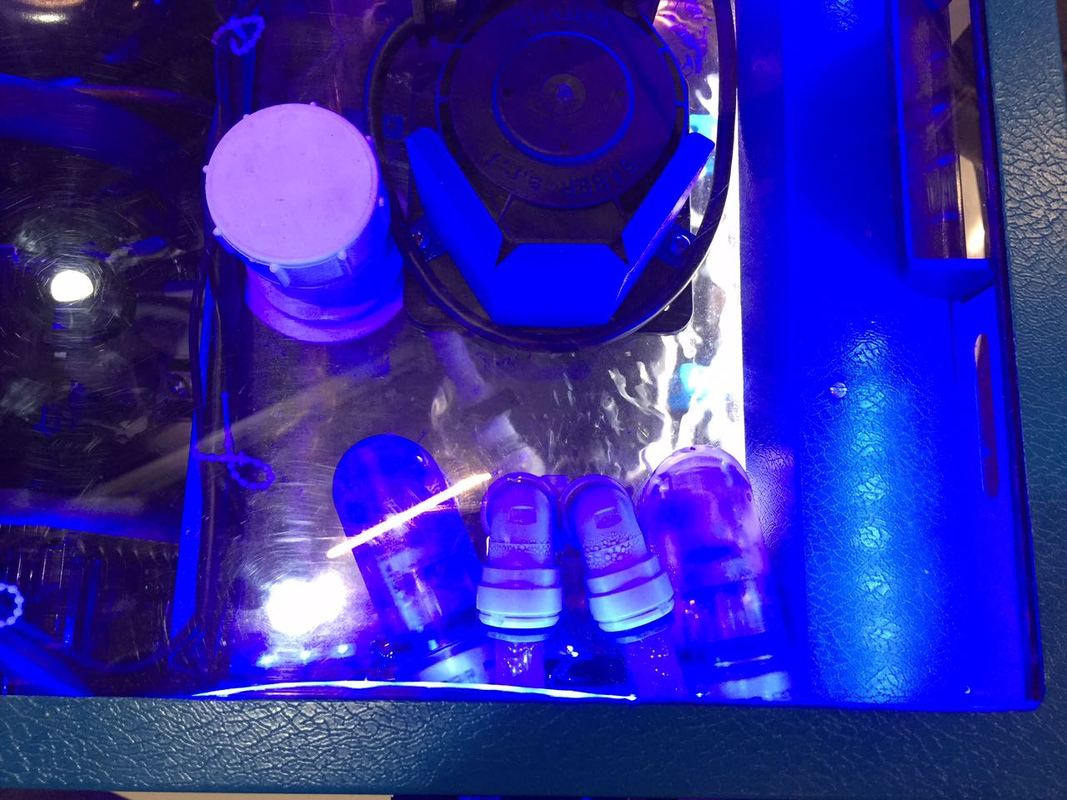

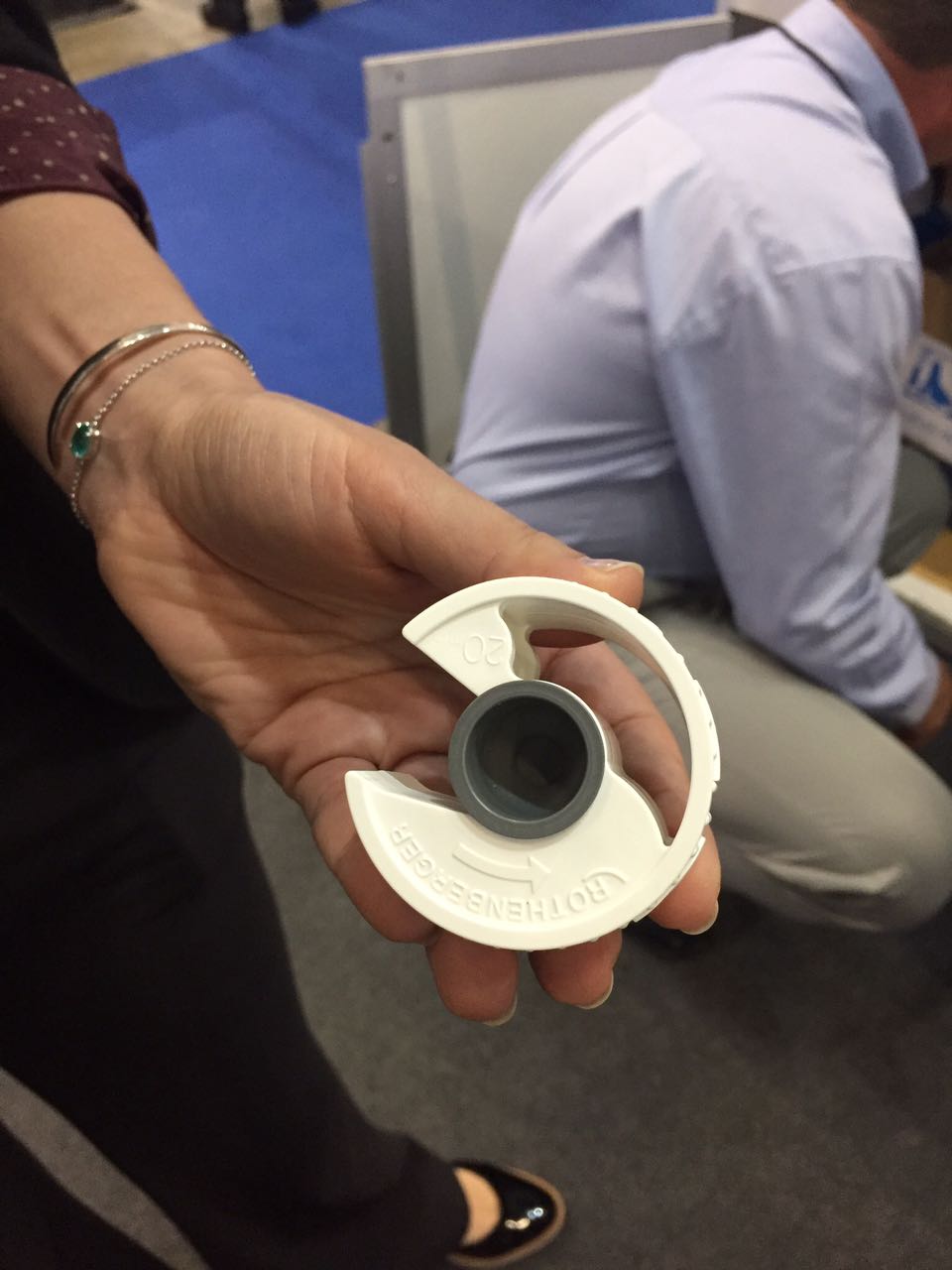

John Guest offers a wide range of push-fit connectors, tube and other fluid control products for drinks dispense and pure water applications. The world’s first food quality push-fit fitting, the John Guest range is now over 800 items strong and provides the quickest and most effective of installations with the quality assurance you would expect. Pushing the tube into the fitting is all that is needed to produce an instant but permanent leakproof connection. The fittings are just as easy to disconnect and re-use without the need for replacement parts. Our Beverage and Drinks Dispense products are produced in FDA compliant materials making them especially suitable for potable liquids.

John Guest fittings work perfectly with Valpar beverage tubing, also represented exclusively by Pasp.

John Guest fittings work perfectly with Valpar beverage tubing, also represented exclusively by Pasp.

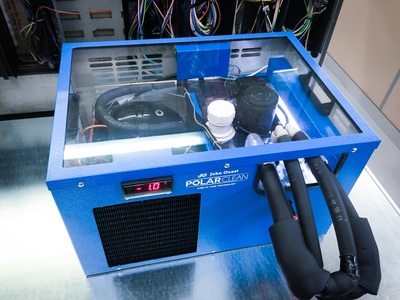

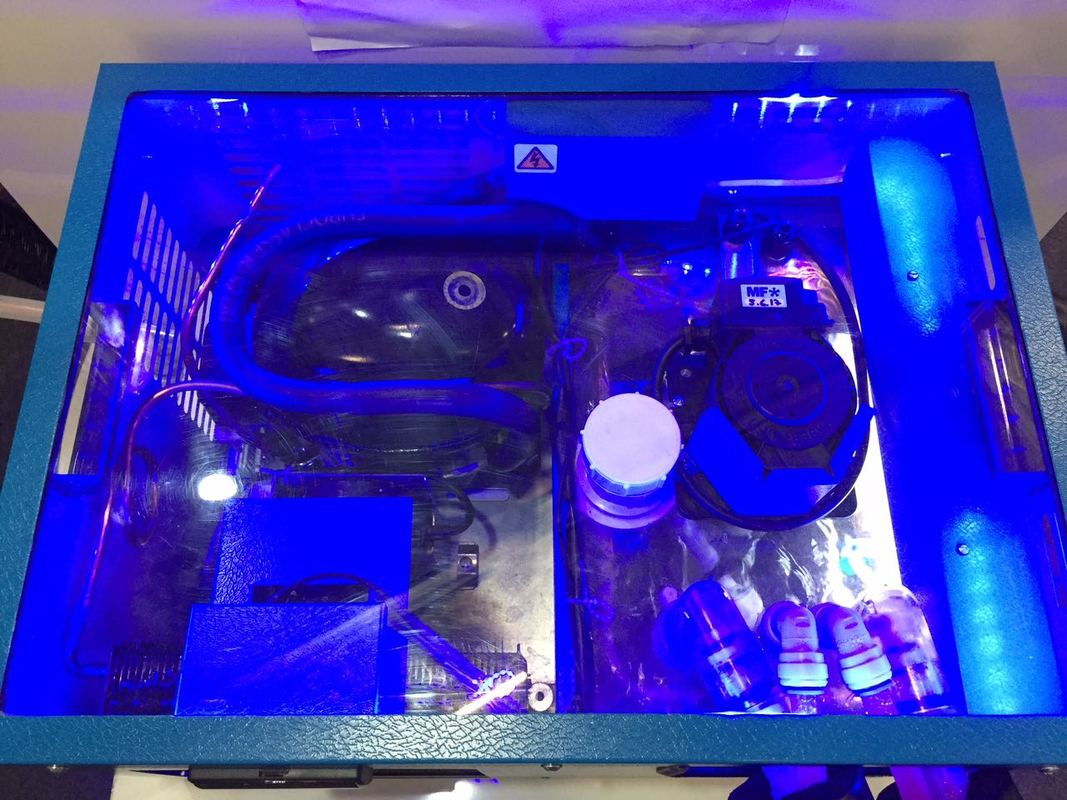

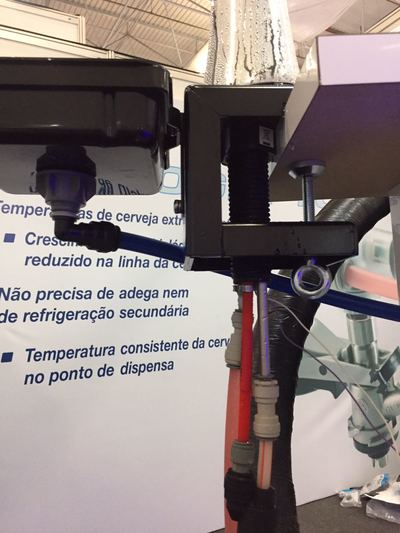

John Guest are pleased to announce the UK market launch of their latest beverage tube-in-tube connectors range – PolarClean®.

Whilst John Guest developed the first tube-in-tube connector over 20 years ago, the range has recently been extended to further satisfy the requirements of a draught beer dispense system, from beer barrel to tap. A tube-in-tube system can help maintain critical temperature conditioning of beer or beverage in the pipeline by enabling each product tube to be fully enveloped by recirculating coolant, usually either water or a water glycol blend, over the entire pipeline length. Subject to system configuration, this may offer significant benefits to the retail outlet, brand owner and consumer when compared to a traditional draught dispense system or packaged product restriction.

The advantages of PolarClean® include:

PolarClean® will be exhibited at the Brau Beviale trade fair for beverage technology in Nuremberg, Germany this November. John Guest are already receiving considerable global interest in this revolutionary product range.

The advantages of PolarClean® include:

- Consistent temperature at pour – to brand specification/customer satisfaction.

- Extra cold temperature capability without necessity of a coldroom or secondary cooling device & associated running/maintenance costs & space utilisation.

- Microbiological activity is reduced at low temperature & product quality is less prone to microbial related complaints e.g. ‘off flavours’, beer fobbing, subject to an appropriate cleaning regime. Less waste means more revenue per barrel.

- Genuine draught dispense where not previously a viable option.

PolarClean® will be exhibited at the Brau Beviale trade fair for beverage technology in Nuremberg, Germany this November. John Guest are already receiving considerable global interest in this revolutionary product range.

Click here to Download the POLARCLEAN® brochure

John Guest Connectors

Click here to download the latest John Guest catalog

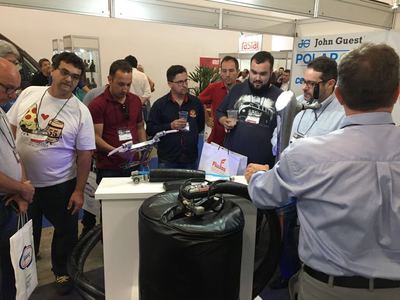

POLAR CLEAN / BRASIL BRAU

|

|

|