ADAITS - Sistema Integrado de Análise de Bebidas Engarrafadas

Atende a norma CFR 21-11 do FDA

AT2E’s ADAITS Online Automated Integrated Tester for Bottled Beverage is a fully automatic quality control system specially developed for bottled beverages launched by AT2E, based on her years of instrument design and production experience, and responding to the application requirements of customers.

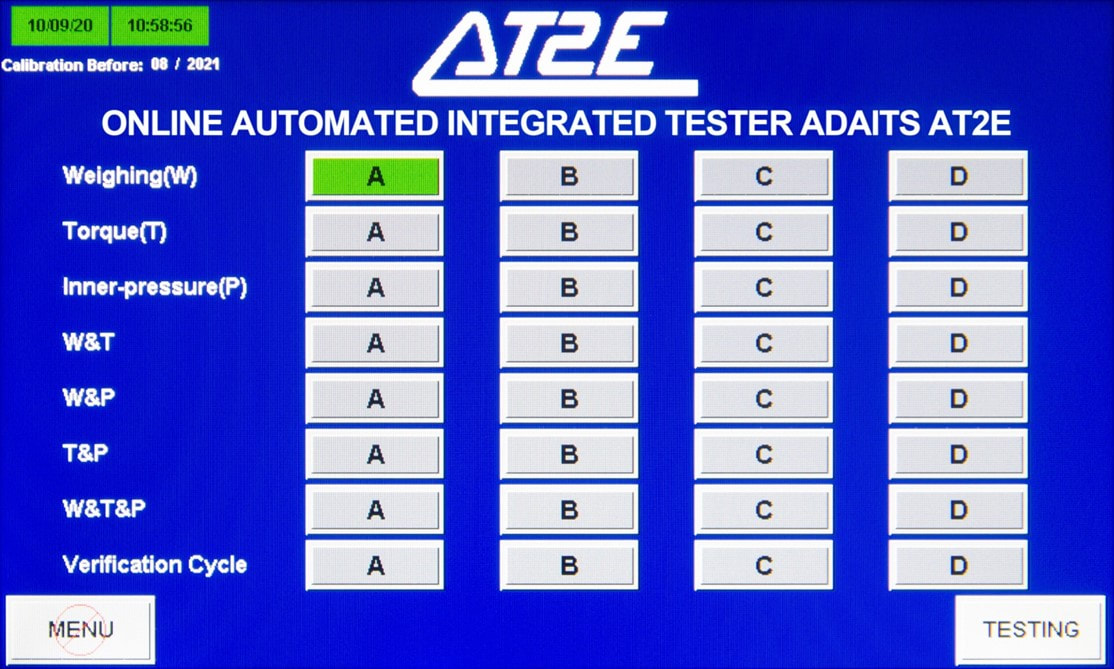

ADAITS consists of several different testing modules, which can be integrated to test torque, weight, application angle, secure seal performance, inner-pressure, top load, etc. Each testing module can be freely combined according to the demand, in order to meet the different testing requirements of customers. Fully automatic testing process and provides testing data for instant inspection, the entire testing process is free of human intervention, which cancels the operators’ influence factors so as to provide the optimal quality control with more accurate and reliable results and better reproducibility.

The system can be chosen to install online with automatic sampling or install in the laboratory as a semi-automatic quality control system with manual sample installation, providing flexible solutions for customers’ quality control management.

ADAITS consists of several different testing modules, which can be integrated to test torque, weight, application angle, secure seal performance, inner-pressure, top load, etc. Each testing module can be freely combined according to the demand, in order to meet the different testing requirements of customers. Fully automatic testing process and provides testing data for instant inspection, the entire testing process is free of human intervention, which cancels the operators’ influence factors so as to provide the optimal quality control with more accurate and reliable results and better reproducibility.

The system can be chosen to install online with automatic sampling or install in the laboratory as a semi-automatic quality control system with manual sample installation, providing flexible solutions for customers’ quality control management.

Features:

Optional testing modules:

- Stainless steel frame with safety door design

- Online testing, unattended test process, cancels all the operators’ influence factors during the test process, much higher reproducibility

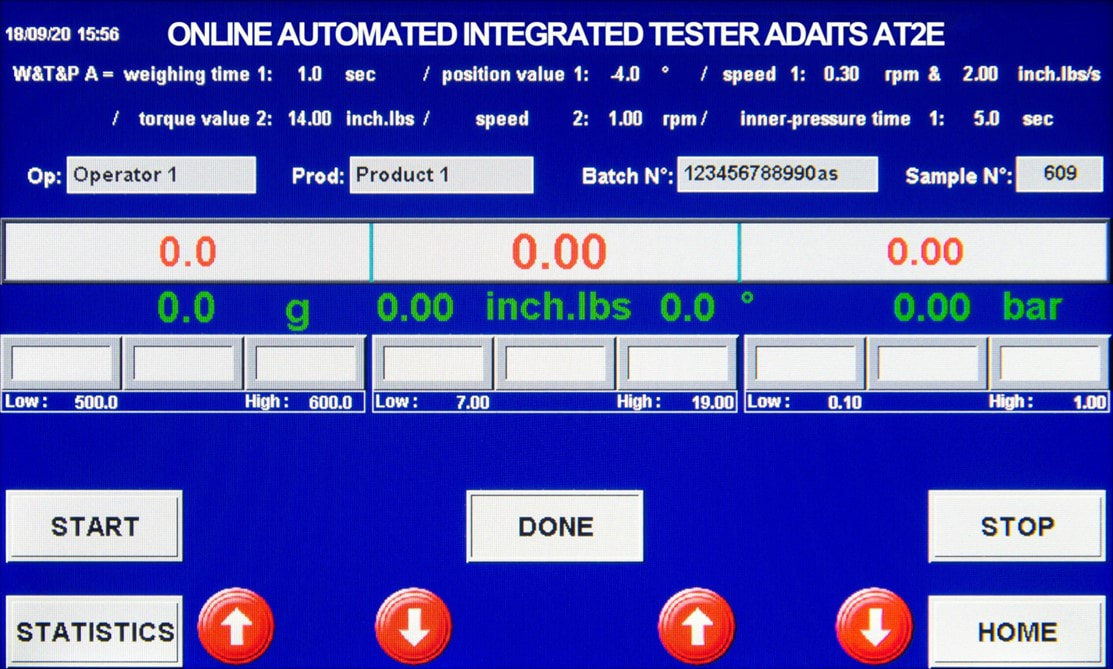

- Servo control and auto sample detection system with PLC and touch screen control

- Customized operation screens and multiple test cycles

- Compatible design with quick-changing bottle adapting inserts and clamps for a variety of different bottle types

- Self-define up to 30 product information, 30 groups of thresholds (limits) and 10 operators’ information. Test information displays on screen, such as test cycle / product information / operator / batch N° / sample N° etc.

- Configuration by password (administrator)

- Auto recording of measurement data during the test process(up to 1000 groups of records), send out real-time data or records.

- RS232C output for printer or data acquisition system or AT2E data management software. The software has data statistics and analysis functions, can generate special charts and reports. The software complies with CFR21-11 / FDA

- Language: English / French / Chinese

- Special auto mode with head number - filler storage

- Three different alarm alerts - buzzer, indication light and on-screen text alerts to notify the operator at the first place in case of any abnormal situation

Optional testing modules:

- Torque controlling module (non-destructive control applicable)

- Weighing controlling module

- Application angle controlling module

- Inner-pressure controlling module

- Secure seal performance controlling module

- Top load performance controlling module

- Other customize controlling modules

Technical specifications (Test Modules):

Technical specifications (General):

- Torque control:

- Measure range: 00.00 to 99.00 Kgf.cm

- Accuracy: ±0.5% F.S.

- Resolution: 0.01 kgf.cm

- Units: Kgf.cm / Inch.lbs / N.cm / N.m

- Weighing control:

- Range: 0 to 4000g

- Resolution: 0.1g

- Unit: g

- Application angle control:

- Measure range: 0 - 360°

- Resolution: 1°

- Inner-pressure control (subject to integrated modules):

- Measure range:

- Stand-alone: 0 to 6.00 bar

- Integrated: 0 to 16.00bar

- Accuracy:

- Stand-alone: ±0.05bar

- Integrated: ±0.5% F.S.

- Resolution: 0.01bar

- Unit: bar

- Measure range:

- Secure seal performance control:

- Measure range: 0 to 16 bar

- Resolution: 0.01 bar

- Accuracy: ±0.5% F.S.

- Top load control:

- Measure range: 0-1500 N (other ranges under request / demand)

- Resolution: 1 N

- Accuracy: ±0.5% F.S.

Technical specifications (General):

- Column stroke: 240mm (other under request / demand)

- Column speed: 5 - 20 mm/s (other ranges under request / demand)

- Star wheel speed: 0.1 - 4 rpm (other ranges under request / demand)

- Measure head rotation speed: 0.01 - 10 rpm (other ranges under request / demand)

- Air supply: 5 - 8 bar (according to the integrated modules, max. 16 bar)

- Power supply: 110 V 60 Hz or 220 V 50 Hz

- Rated power: 1800W

- Output: Standard RS232 serial port, for PC or printer